Open segment bowl 48 segments 23 rows the top two are solid segmented rings the top one is Paduak and the second is Yellowheart, I may add a thin Maple we'll see. Should be 1057 pieces.

Well I've designed it in WTP, also approximated it in Segment Pro to get the 3d view and the paint page.

All the wood for the open-segment pieces are milled and the first open-segment row is glued and sanded

WTP screen shot

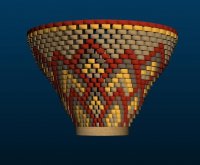

This is the approximation view from Segment Pro

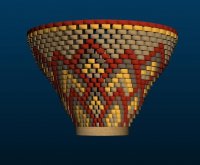

The paint page form Segment Pro

Now I have hand written the segment count across the bottom, trying to keep the right order for the colors.

I'm using four different species Maple, Padauk, Yellowheart, & Chakte-viga

I have the summary from Segment Pro (attached PDF) but the profile is a little different then the one I did in WTP (attached PDF) so I'm only have that as a reference.

To figure out how much of each wood to mill I used the export to Excel CSV and did a little work in Excel (attached)

I have the segments cut for the first three rows, I've made then the same diameter so I have some less setup time.

The first row glued on and sanded it flat.

Well I've designed it in WTP, also approximated it in Segment Pro to get the 3d view and the paint page.

All the wood for the open-segment pieces are milled and the first open-segment row is glued and sanded

WTP screen shot

This is the approximation view from Segment Pro

The paint page form Segment Pro

Now I have hand written the segment count across the bottom, trying to keep the right order for the colors.

I'm using four different species Maple, Padauk, Yellowheart, & Chakte-viga

I have the summary from Segment Pro (attached PDF) but the profile is a little different then the one I did in WTP (attached PDF) so I'm only have that as a reference.

To figure out how much of each wood to mill I used the export to Excel CSV and did a little work in Excel (attached)

I have the segments cut for the first three rows, I've made then the same diameter so I have some less setup time.

The first row glued on and sanded it flat.