You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Open Segment Project - Acoma

- Thread starter Bob Beaupre

- Start date

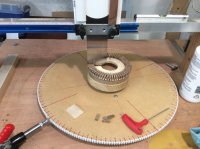

Turned and sanded the ID up to row 18 this morning.

Got rows 19, 20, 21 & row 22 is on and drying. After facing I put on 23 & 24 tonight.

The ID starts pulling in at 24 so it looks like it's time to finish turn and sand up to 23.

It'll be slower from there as I don't want the ID to get to small to get at the previous rows so I'll put on two row and then finish two rows. We are getting close where I get to try a solid ring with the new fixture.

That should be interesting

That should be interesting

Got rows 19, 20, 21 & row 22 is on and drying. After facing I put on 23 & 24 tonight.

The ID starts pulling in at 24 so it looks like it's time to finish turn and sand up to 23.

It'll be slower from there as I don't want the ID to get to small to get at the previous rows so I'll put on two row and then finish two rows. We are getting close where I get to try a solid ring with the new fixture.

That should be interesting

That should be interesting

Bob, got your zip file for the sketchup drawing. Looks good.Mike let me know if you need any additional information, I'll be glad to help

By any chance do you have a parts list for the jig? I am looking to build a non motorized (not pc controlled), jig this summer. Mainly interested in your parts for the vertical rack and the stops to hold in at heights.

I'll put it together for you

Bob, got your zip file for the sketchup drawing. Looks good.

By any chance do you have a parts list for the jig? I am looking to build a non motorized (not pc controlled), jig this summer. Mainly interested in your parts for the vertical rack and the stops to hold in at heights.

Mike for the vertical rack I used Linear rails and bearings from Title: Phidgets Inc. - Unique and Easy to Use USB Interfaces

The two rails are: Title: Phidgets Inc. - LMN4002_0 - Linear Shaft 16-1000mm they were 10.00 each

The four bearings are: Title: Phidgets Inc. - LMN4219_0 - Flanged Linear Bearing for 16mm Shaft they were $4.10 each

The Rail/shaft supports are: Title: Phidgets Inc. - LMN4223_0 - Shaft Support (Pillow) for 16mm Shaft (2pcs) you need four of then they come in pairs so you need two packs at $3.55 each

I put a toggle clamp on the side for easy temporary clamping, it puts some side push and moves the support a little so I only use to make adjustments once those are locked in I release this temporary toggle. For the main lock of the vertical rack I just use a T-rail from Woodcraft and a angle bracket

I can take some close up pictures of things if that would help.

Also, if you pull the sketchup drawing apart you will notice that the 3/4" MDF base is two layers of MDF, I wanted the base really solid as I put two 3/4" flanged bronze bushing in it of the shaft to turn on. Not shown on the sketchup drawing is a third 3/4" flanged bronze bushing separated from the base. In between I have my timing gear for the attachment to the stepper motor

Thanks Bob for your list. It will help in my build. I know when I do mine it will be a manual turn.

I have been looking at the vids from this site.: I basically want a pretty simple jig to build. Your list of materials will help.

Title: Open Segment Jig

I have been looking at the vids from this site.: I basically want a pretty simple jig to build. Your list of materials will help.

Title: Open Segment Jig

Bob, once again amazing work.

Thanks for posting.

Fixture is working very well

Tom Lohman

Tom Lohman

Bob, your piece is looking great. For me watching the pattern come out almost feels like watching my kid grow up

Tom the more I work on this one the more I'm liking it. The pattern and colors are coming out great. I'm hoping I picked a profile good enough for the pattern.Bob, your piece is looking great. For me watching the pattern come out almost feels like watching my kid grow up

Row 26 is on and it's pulling in.

1 mega watt reactor, did not want to go to big

Actually a size I got back when I worked in metal fabrication

Actually a size I got back when I worked in metal fabrication