Jim Grieco

PRO Member

Hello,

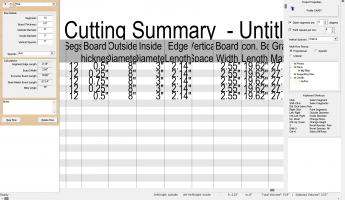

Recently I needed to make 4 rings for a project I am working on. All 4 rings needed to be 8" OD and 3" ID. When creating them in WTP, this is what I entered for the OD & ID. When I built the rings after using the cut list from WTP. I then measured the ID of the rings and they all were at 4" not 3".

Usually I am not that critical with measurements in a design so this was the first time I actually measured the rings. Cannot say whether it is always like this or not.

Anyway, what could I have possibly done wrong since I entered the specific ID when creating the rings?

Thanks

Recently I needed to make 4 rings for a project I am working on. All 4 rings needed to be 8" OD and 3" ID. When creating them in WTP, this is what I entered for the OD & ID. When I built the rings after using the cut list from WTP. I then measured the ID of the rings and they all were at 4" not 3".

Usually I am not that critical with measurements in a design so this was the first time I actually measured the rings. Cannot say whether it is always like this or not.

Anyway, what could I have possibly done wrong since I entered the specific ID when creating the rings?

Thanks