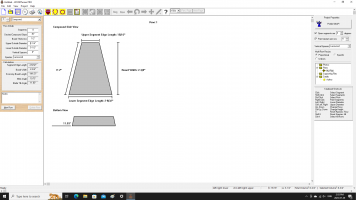

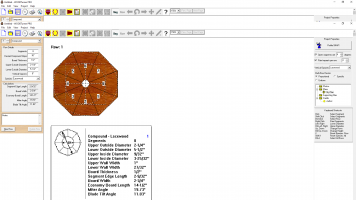

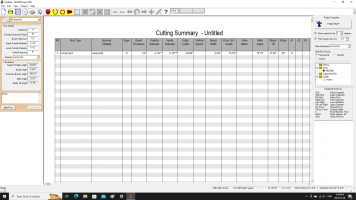

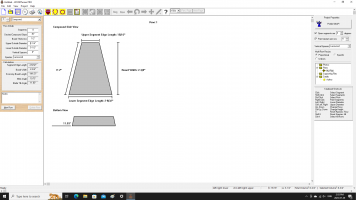

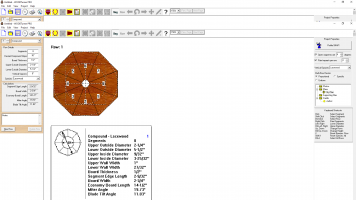

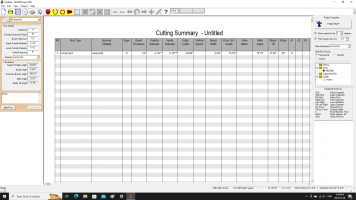

I have tried to cut a compound staved lid at 30 deg. I payed close attention to my saw set up using a digital angle meter for the blade tilt and a Incra miter guage.

After several attempts i feel i should ask the skilled for advice and to point out my errors. I cut my test pieces to length and width and made my compound and miter cuts, failed. I have also tried cutting them from oversized pieces still a no go. Any suggestions would help. I am only a yearling to wood turning i have 0 problems with segmenting it is just these dang compounds that have me in a dizzle.

After several attempts i feel i should ask the skilled for advice and to point out my errors. I cut my test pieces to length and width and made my compound and miter cuts, failed. I have also tried cutting them from oversized pieces still a no go. Any suggestions would help. I am only a yearling to wood turning i have 0 problems with segmenting it is just these dang compounds that have me in a dizzle.