I'm back from wood shopping. Just need to rip out my material form two more species of wood, then I can run them thru the planner and start my new bowl. With the new jig I'm only going to bump up to a 60 segment per row bowl for starters. I'm going to use of Tom Lohman's designs but am putting it on a different bowl profile. It has a total of 2040 segments

-

Are you looking for a coupon code to buy my software? You can get one from lots of 3rd party sites but they won't work. My software never goes on sale and has never been discounted. The only coupon codes that are given is when I give a club presentation and I offer a discount to the attendees. Other than that, everyone pays the same price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

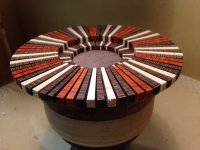

Open Segment Project "Interwoven"

- Thread starter Glenn McCarron

- Start date

Glenn McCarron

PRO Member

I'm back from wood shopping. Just need to rip out my material form two more species of wood, then I can run them thru the planner and start my new bowl. With the new jig I'm only going to bump up to a 60 segment per row bowl for starters. I'm going to use of Tom Lohman's designs but am putting it on a different bowl profile. It has a total of 2040 segments

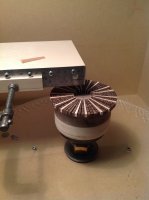

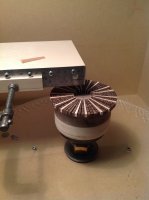

Hi Bob, looking forward to seeing your new design and your new jig in action. I did a little bit of tweaking to my jig this morning and was able to get under way with cutting my first round of segments, BOY THEY ARE SMALL. I also glued up the waste block and the first solid disk. I'm thinking I'm going to change out the angle aluminum as well and add a much thinner piece.

Glenn McCarron

PRO Member

Did get row 1 back on today. Had a little miscalculation on the first attempt and had to turn it back off. It gave me a bit of practice flattening the disc then shaping it a bit. That unfortunately did not go so good as the thin ends basically tore off. This scares me a bit for the next time. I will wait until I have three or four rows on before I try turning the inside shape.

IF ANYONE HAS SUGGESTIONS ON TURNING THESE DELICATE LITTLE PIECES PLEASE LET ME KNOW.

I did use a stainless steel ruler in place of the angle aluminum. It is much thinner and even allowed me to place the last segment. It also provides the measure for the outside dimension.

IF ANYONE HAS SUGGESTIONS ON TURNING THESE DELICATE LITTLE PIECES PLEASE LET ME KNOW.

I did use a stainless steel ruler in place of the angle aluminum. It is much thinner and even allowed me to place the last segment. It also provides the measure for the outside dimension.

They are small my first row the SEL is 0.17".

Do like Tom Lohman, use a power sander to start with

Do like Tom Lohman, use a power sander to start with

I saw a vid years ago from a woodturner who turns very small stacked laminated pieces (1/16th - 1/8) that was separated by small wood bars. He placed the glued up blank into a coffee can and poured in heated/melted paraffin wax. The wax filled in all the small spaces and provided support to the very thin wood. Basically the flimsy blank became a solid blank. Once cooled he would mount the piece on the lathe and turn his design. Once done, he would use a heat gun to melt the wax from the fragile shaped turning.

I know this is not much of a description of the process and I am not sure how well it would be used in your bowl project. I could see building up the segmented piece to a logical stopping point, doing the wax thing and turn to shape. Then cleaning up the top, adding layers, and repeating. Just a thought on how to support very thin pieces for turning.

I will admit I have not done this process yet.

I know this is not much of a description of the process and I am not sure how well it would be used in your bowl project. I could see building up the segmented piece to a logical stopping point, doing the wax thing and turn to shape. Then cleaning up the top, adding layers, and repeating. Just a thought on how to support very thin pieces for turning.

I will admit I have not done this process yet.

Last edited:

peter white

PRO Member

Very interesting it must work ok only drawback I can see is you would have to have a wax finish. Can't see any way to remove wax for other types of finish.

Glenn McCarron

PRO Member

I saw a vid years ago from a woodturner who turns very small stacked laminated pieces (1/16th - 1/8) that was separated by small wood bars. He placed the glued up blank into a coffee can and poured in heated/melted paraffin wax. The wax filled in all the small spaces and provided support to the very thin wood. Basically the flimsy blank became a solid blank. Once cooled he would mount the piece on the lathe and turn his design. Once done, he would use a heat gun to melt the wax from the fragile shaped turning.

I know this is not much of a description of the process and I am not sure how well it would be used in your bowl project. I could see building up the segmented piece to a logical stopping point, doing the wax thing and turn to shape. Then cleaning up the top, adding layers, and repeating. Just a thought on how to support very thin pieces for turning.

I will admit I have not done this process yet.

Interesting concept Mike. He has some unique turnings.

Art Bodwell

PRO Member

Haven't tried it, but what about putting ca glue on them to harden them, the way you filled cracks or punky wood. Just a thought

Glenn McCarron

PRO Member

Thanks everyone who responded in regards to turning these delicate segments. I did re-make the first row and again after flattening I managed to damage the outside overhang. I used this as an opportunity again to try power sanding the centre to establish the profile. This did take a bit of time and was mostly successful in cutting the profile. What I didn't like was the finished profile in that it didn't have a nice crisp line to it and there were also a few segments that had chipped back a bit from the taper edge.

I have a few family issues going on in the next few weeks so I will probably not get back to it for a while. I will have to contemplate my next move. I may go back to 60 segments or I may try doing it as a closed segment project.

Like I had said before I have a new sense of respect for those that do these high density projects. I cannot imagine doing 144 pieces but there are folks that do it very successfully.

I have a few family issues going on in the next few weeks so I will probably not get back to it for a while. I will have to contemplate my next move. I may go back to 60 segments or I may try doing it as a closed segment project.

Like I had said before I have a new sense of respect for those that do these high density projects. I cannot imagine doing 144 pieces but there are folks that do it very successfully.

Bluemax

PRO Member

I use my 10" table saw with a sled to cut segments as small as 0.120" (SEL) and it works fine. I use Tom Lohman's method of gluing the strips of wood together at one end so I can easily cut more than one at a time (typically I use 4 strips) and a single hold-down block that clamps both the strips and the segments being cut. If that doesn't make sense, I could send you a photo of the setup. I also use a 1/16" thick blade made by total Saw Solutions. They are expensive but are terrific blades and save a lot of wood when cutting thousands of segments. Hope this helps.

I took your advice an ordered a Total Saw Solutions blade. I am very impressed. It takes almost no effort to cut through very hard wood and the cut is very smooth. For segments it works extremely well in that you don't send any more expensive dust into the vacuum than you have to. The people there are very helpful and it is an American Company with products made in America. Go to their website and view their blade in action. The blades are not cheap but they work far better than the normal blades we use. I was using a $130 Forrest woodworker II blade which was O.K. but was not as good as this blade. I consider this a significant upgrade. It will make any saw perform much better. Also to any Shopsmith owners I put a review in their Forum on the blade. You will need to make some adjustments to the lower saw guard because of the blade balancers.

Last edited:

Glenn McCarron

PRO Member

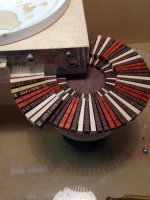

So yesterday I was able to get a bit of shop time. I have adjusted my ruler on my Driskell Jig as I was not quite on centre. It had the effect of making the ring but slightly off centre. When I put it on the lathe it was very evident that it was not quite centred as the ring had a off centre rotation. I did recut my segments having adjusted the angle slightly due to an oversight on my part ( That's a story by itself). The segments were re-glued and are now ready to be flattened as they have dried overnight.

Through another situation I ended up needing to buy a new crosscut blade. Short of ordering online like some folks have suggested above in this thread I did buy a Diablo 90 tooth carbide Ultra Flawless Finish crosscut blade. I am EXTREMELY pleased with the quality of the cut and the lack of any fuzzies to deal with.

I hope today to get row 2 completed.

Through another situation I ended up needing to buy a new crosscut blade. Short of ordering online like some folks have suggested above in this thread I did buy a Diablo 90 tooth carbide Ultra Flawless Finish crosscut blade. I am EXTREMELY pleased with the quality of the cut and the lack of any fuzzies to deal with.

I hope today to get row 2 completed.

Glenn McCarron

PRO Member

Nice job Glenn, nice and easy on the first three or four rows

Glenn McCarron

PRO Member

Thanks Bob, I will probably do 3 or 4 rows before I try to turn anything like you suggest.Nice job Glenn, nice and easy on the first three or four rows

Glenn McCarron

PRO Member

Unfortunately I have not been able to give my project my full attention lately but I'm sure that will change.

I was relatively happy with how my second row went together the other day. Yesterday I flattened it off and upon close inspection I realized I had made a fatal mistake. I was using the 144 hole index but using every second hole to make it 72 pieces. After the first row I moved the index ahead by one hole to stagger the next row. What I should have done was move the index BACK one hole. Consequently the pattern was compromised. I was able to turn off layer two without hurting layer one. It has been re-flattened and is now ready for row two to go back on again. Hopefully I will get an opportunity to do that today. Have to re-cut segments first.

I was relatively happy with how my second row went together the other day. Yesterday I flattened it off and upon close inspection I realized I had made a fatal mistake. I was using the 144 hole index but using every second hole to make it 72 pieces. After the first row I moved the index ahead by one hole to stagger the next row. What I should have done was move the index BACK one hole. Consequently the pattern was compromised. I was able to turn off layer two without hurting layer one. It has been re-flattened and is now ready for row two to go back on again. Hopefully I will get an opportunity to do that today. Have to re-cut segments first.

Glenn McCarron

PRO Member

Lesson learned check the pattern

Glenn McCarron

PRO Member

I would semi-finish it, you have WAY more better access now then a few row from now. Layout the ID of row five so you stop before you hit the glue line, it also gives you a reference for the taper. And I know I don't have to say it BUT take it VERY slow