Thank you for this. I didn't attach a file because that wasn't created from a file. In fact. I have yet to turn anything from a file yet, I still don't understand Lloyd's spreadsheet fields and how to figure out what to cut first. I don't use his chop saw jig, I like Jerry Bennett's wedgie sled.

A lot of us use Bennett's wedgie sled. The sled is easy to make.

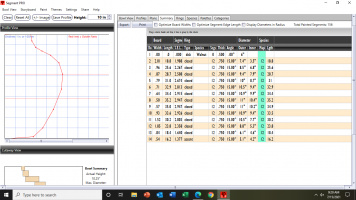

I attached a quick simple summary sheet from SP. Going from left to right.

Row - same as ring. 1 is always the base

Width - how wide the board stock needs to be to cut the segments

Length - how long of a board you need to have enough material to cut segments

Ring SEL- Segment Edge length for that ring

Ring Type - closed, open, disk, etc.

Ring Species- type of wood

Ring Seg- number of segments for that ring

Ring Thick- height (thickness) of the stock

Ring Angle- miter angle to be used to cut the segments

Diameter Outer - Outside diameter of the segmented ring

Diameter Inner - Inner diameter of the segmented ring

Species - wood species (other species will show up if you paint your with a pattern

Species Length how much material you need to cut the segments.

I bet you do something similar to what I do

- prep the stock

- cut stock to the length and width needed to cut segments.

- cut segments.