D

Daniel Shuflin

Guest

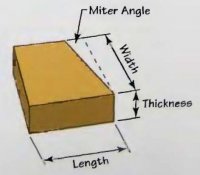

Hello all. I am new to this site and segment turning. I am in SW Washington and just recently have started turning. I have researched this question and cannot find an answer. When cutting your segments the outside segment length is supposed to be 2.775". Does your piece of wood supposed to be ripped to this size before you start. Then leave your fence set at this width to cut your segments. Thanks I am sure you will be hearing more from me in the future. Looks like I posted this in the wrong forum, sorry about that.

Last edited by a moderator: