pete marken

PRO Member

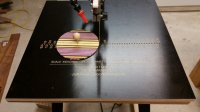

The fixture was designed for bowl from a board especially vortex style. The fixture is made from 12 mm baltic birch plywood sanded but un-finished and measures 15" X 14-3/4". Phenolic coating on 1/2" material is no longer available. The pin holes are precision drilled for exact ring diameters and will cut a very nice circle, the text is engraved. There is no need to lay out circles with a compass, lay out diameters with a ruler on one side. Then drill holes for the blade and center pin and cut. This greatly reduces scroll saw time. The hole spacing is for a ring diameter increase of 1/4" (1/8" radius increase). The cost is $75 plus shipping. The fixture is clamped or screwed to your scroll saw table. If interested please contact me by e-mail (p_marken@bellsouth.net)

The fixture was designed for bowl from a board especially vortex style. The fixture is made from 12 mm baltic birch plywood sanded but un-finished and measures 15" X 14-3/4". Phenolic coating on 1/2" material is no longer available. The pin holes are precision drilled for exact ring diameters and will cut a very nice circle, the text is engraved. There is no need to lay out circles with a compass, lay out diameters with a ruler on one side. Then drill holes for the blade and center pin and cut. This greatly reduces scroll saw time. The hole spacing is for a ring diameter increase of 1/4" (1/8" radius increase). The cost is $75 plus shipping. The fixture is clamped or screwed to your scroll saw table. If interested please contact me by e-mail (p_marken@bellsouth.net)

Last edited: