Let me start by saying that I do not use indexing wheels with open segments so I do not profess any expertise with this technique.

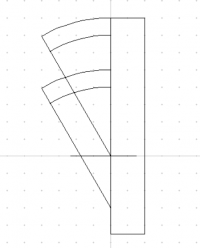

However, If you are using an index wheel with 24 divisions, that would assume that you are using closed segments and the angle for cutting those segments is 7.5 degrees. If you are using open segments using Segment PRO, the segments have been cut at 5.5 degrees. If you are aligning the edge of a 5.5 degree segment with a fence that is expecting 7.5 degrees, the other edge will NOT point to the center.

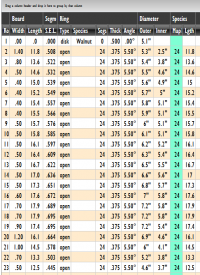

The gap of a 24 segment open-segment ring is 4 degrees. That means that if you are using an index of 24, you would need to account for the 2 degrees of space that will be on both sides of each 5.5 segment. It is no longer a 24-segment ring. It is 24 segments.

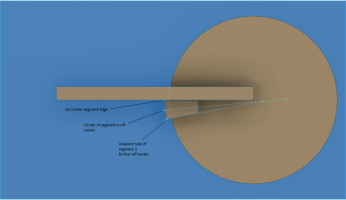

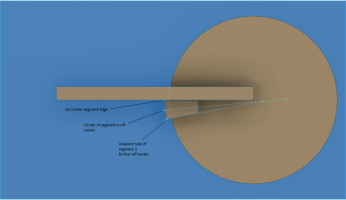

A 24-segment open segment ring is actually 48 segments. 24 segments are wood cut at 5.5 degrees and 24 segments of space that is 1/6” of the width of a 24- segment closed-segment ring.

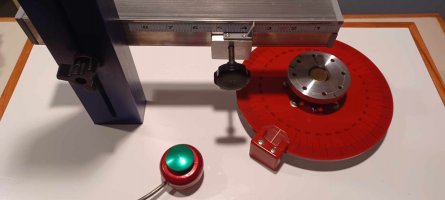

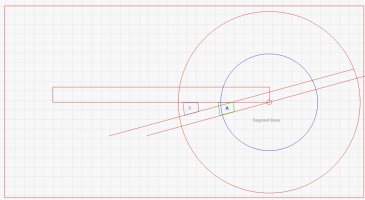

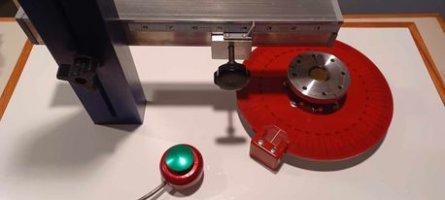

In other words, you need a SegEasy Plate for 24 segments. This has 24 channels and 24 spacers that add the space for the open space. This means that cutting segments at 5.5 degrees give you segments that slide into the channels with accurate spacing and every edge points to the exact center of the ring.

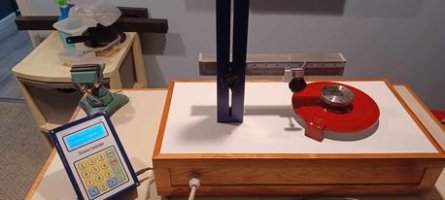

If you’re not going to use the Stomper (my product), you can get a 24, 36 or 48 segment jig from Jerry Bennett at

Title: Seg-Easy Solutions.

You might be able to do this with an indexing solution but you’ll need to go to Tom Lohman’s site to see how to account for the open space. It might be as simple as cutting all the segments at 7.5 degrees.

The other choice is to use closed segments.