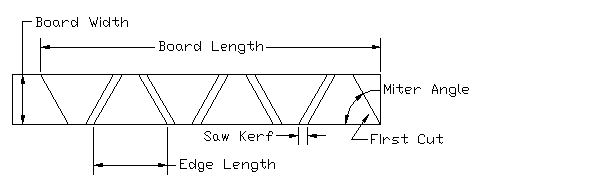

Given the notion that the number of segments divided into the circumference of a bowl gives you the Segment Edge Length, I'd like to understand why there's a difference in the SELs in Segment Pro vs a plain calculation. For example: for a 6" 12 segment bowl the formula would be (3.1416 * 6 ) / 12. That, rounded, equals to 1.571", yet the SEL in Segment Pro returns 1.608". Anyone know why that is? Is my "notion" incorrect? I have a attached a .json of a straight walled bowl to test this calculation and I do get 1.608 SEL for the above bowl.

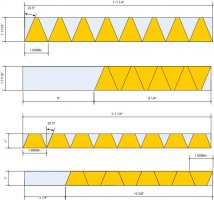

Another question is why did the segments get automatically wider when the outside profile is vertical? And more interestingly, if the SELs for all rings are 1.608 why would the board length be different from one to the next? I have a suspicion it is due to the fact that the segment widths are different which makes the savings in length when flipped at cut time (or using the alternate fence) vary because of the width change... if that made sense. TIA

Another question is why did the segments get automatically wider when the outside profile is vertical? And more interestingly, if the SELs for all rings are 1.608 why would the board length be different from one to the next? I have a suspicion it is due to the fact that the segment widths are different which makes the savings in length when flipped at cut time (or using the alternate fence) vary because of the width change... if that made sense. TIA