Greetings Everyone,

I'm a semi-newbie, getting back into woodworking with my grandson after several decades away (I have to work for a living!).

I recently acquired a used 2 HP variable speed full size lathe and plan to make Kevin's Round Bowl as my first project.

I've already bought the purpleheart and maple locally and ordered the holly and blackwood (dyed) veneers. This weekend I hope to start cutting and

making the rings. I plan to take pictures as I progress and of the finished bowl.

I have a few questions and would appreciate any helpful advice.

1. How is the base fastened to the lathe faceplate? Is the metal faceplate screwed to an extra piece of wood on the bottom of the bowl?

Or is disk one (purpleheart) of the bowl screwed directly to the lathe faceplate?

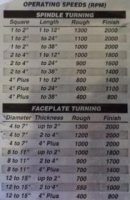

2. What rotational speed (rpm) or cutting speed (feet per minute) would be recommended for cutting the bowl?

Thanks,

John

I'm a semi-newbie, getting back into woodworking with my grandson after several decades away (I have to work for a living!).

I recently acquired a used 2 HP variable speed full size lathe and plan to make Kevin's Round Bowl as my first project.

I've already bought the purpleheart and maple locally and ordered the holly and blackwood (dyed) veneers. This weekend I hope to start cutting and

making the rings. I plan to take pictures as I progress and of the finished bowl.

I have a few questions and would appreciate any helpful advice.

1. How is the base fastened to the lathe faceplate? Is the metal faceplate screwed to an extra piece of wood on the bottom of the bowl?

Or is disk one (purpleheart) of the bowl screwed directly to the lathe faceplate?

2. What rotational speed (rpm) or cutting speed (feet per minute) would be recommended for cutting the bowl?

Thanks,

John