-

Are you looking for a coupon code to buy my software? You can get one from lots of 3rd party sites but they won't work. My software never goes on sale and has never been discounted. The only coupon codes that are given is when I give a club presentation and I offer a discount to the attendees. Other than that, everyone pays the same price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Line Laser

- Thread starter rtaylor

- Start date

rtaylor

PRO Member

Thanks Mark, I am familiar with that post. I followed it years ago too. The laser dot is not the same as a line laser that actually shows where the blade will cut in a straight line. All my glue up stuff is patterned after Lloyds ideas. The dot, although good, leaves a little to be desired.

Doug Drury

PRO Member

I'm just starting to get back to a multi gen glue up I started a couple of years ago. A move had me put the 1st generation aside. To answer your question, I built a jig years ago that had adjustable fences and a laser line attached to the jig that shone down the saw blade. It worked "kind of". My issue was the laser was not very bright and my hold downs were awkward to use and not that effective. I'm going to revisit this in the next week or two. If there is interest I will report back with some pics and revised (hopefully better) solutions.

I wouldn’t sell the laser dot idea short as it works better than anything else I’ve tried. If you have the ability to mount it on a flexible arm on a magnetic base, mount it so that it is a couple inches in front of the blade and high enough so that it won’t be bumped. Next, put a scrap board that is the same thickness as your board on your miter at the target angle and push into the blade and then pull it back without letting it change its position on the fence. The kerf the blade made is now in perfect alignment with the blade. Next, move the laser so that the beam is perpendicular to the table and point it into the kerf. Your laser dot is now perfectly aligned with the blade. If your laser isn’t at the perfect angle, it won’t matter because the scrap board is the same thickness as your laminated board and so the registration of the beam and your target is correct at the point of intersection.Thanks Mark, I am familiar with that post. I followed it years ago too. The laser dot is not the same as a line laser that actually shows where the blade will cut in a straight line. All my glue up stuff is patterned after Lloyds ideas. The dot, although good, leaves a little to be desired.

Next, put your laminated board that has all of the targets marked and slide it along the fence and push the sled forward or backward until the laser dot is perfectly aligned under the first dot and finish the cut. Repeat for all of the dots and when you’re done, turn each strip up on its side and you’ll find that they will all be nearly identical in width.

This is the method I used to make my bird design about six times now and the results have always been as good as the bowl on the home page of the website and that is a 3rd generation design.

You will find that trying to make a laser line perfectly match the plane of the blade will be very difficult. Perhaps you’ll be able to change my mind, though. :->

Lloyd

Doug Drury

PRO Member

Sorry for the late reply, but following is what I've come up with.

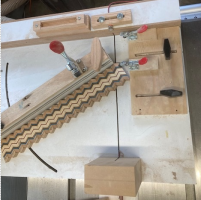

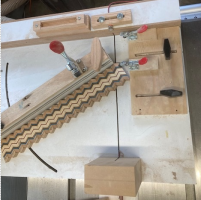

Here is a pick of the original sled. You can see the laser at the top of the picture. Adjustment for horizontal alignment with the blade is accomplished with the slot in the mounting bracket.

The problems I had with this sled are:

Here is a pick of the original sled. You can see the laser at the top of the picture. Adjustment for horizontal alignment with the blade is accomplished with the slot in the mounting bracket.

The problems I had with this sled are:

- The laser itself. With it being so close to the sled table, you could not focus the laser sharply along the length of the saw kerf. It would be wide at one end, sharp and narrow at the other, so you were always "guessing" exactly where the cut would be.

- The old down clamps either didn't reach the piece, or were in the way or wrong orientation

- While not shown in the holder beside the laser, the battery compartment didn't hold the batteries that well, and a third battery should have been added (the holder only holds two) to increase the brightness of the laser.

- I thought the t-track on the fence was a good idea so I could slide and position stops, hold downs, etc. on it. In practice I found if more trouble than it was worth and it didn't really work as envisioned.

Doug Drury

PRO Member

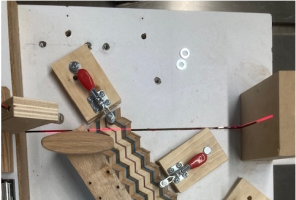

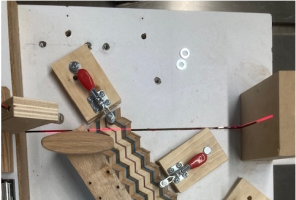

Changes I made to the sled:

The hold downs. I have a bunch of t-nuts. I made some little blocks and attached the hold down to them. Then I drilled a through hole in the blocks to hold a bolt. I then drilled strategic holes for the t-nuts in the base with a recess for the head of the t-nut. This allows me to place a hold down wherever I want it. When I went to put this is practice, I found that multiple holes in the block with the hold down clamp allowed for fine adjustment without making the base of the sled into swizz cheese.

The Laser:

I made a mount for the laser that raises it higher on the table than before. I also purchased a proper batter holder that holds three batteries (I use rechargable AA cells to power the laser).

While this helped the brightness issue, it was only marginally successful in the alignment and focus issue. I think Lloyd is on the right track with attached the laser (in his case point instead of line) to the table instead of on the sled. My table saw is stationary and does not move, so I think I will look at some sort of over-arm mount that I can fine tune and position right above the saw and kerf. This will let me focus the laser in line with the saw blade (kerf) and even focus the laser to the same width as saw kerf.

The hold downs. I have a bunch of t-nuts. I made some little blocks and attached the hold down to them. Then I drilled a through hole in the blocks to hold a bolt. I then drilled strategic holes for the t-nuts in the base with a recess for the head of the t-nut. This allows me to place a hold down wherever I want it. When I went to put this is practice, I found that multiple holes in the block with the hold down clamp allowed for fine adjustment without making the base of the sled into swizz cheese.

The Laser:

I made a mount for the laser that raises it higher on the table than before. I also purchased a proper batter holder that holds three batteries (I use rechargable AA cells to power the laser).

While this helped the brightness issue, it was only marginally successful in the alignment and focus issue. I think Lloyd is on the right track with attached the laser (in his case point instead of line) to the table instead of on the sled. My table saw is stationary and does not move, so I think I will look at some sort of over-arm mount that I can fine tune and position right above the saw and kerf. This will let me focus the laser in line with the saw blade (kerf) and even focus the laser to the same width as saw kerf.

Looks like a great solution, Doug.

Mounting the laser on a magnetic base directly on the saw table works great if you can do it with the sled you want to use. Mounting it on the sled will also work but moving the laser with the sled introduces issues that won't exist with a stationary setup.

Thanks for posting this.

Lloyd

Mounting the laser on a magnetic base directly on the saw table works great if you can do it with the sled you want to use. Mounting it on the sled will also work but moving the laser with the sled introduces issues that won't exist with a stationary setup.

Thanks for posting this.

Lloyd