HI,

I'm working on my 1st bowl and am perplexed on how to cut the feature ring lamination.

Segment Pro gives me a board width of 1.20, length 42.2, S.E.L. 5.0, 9 segments, 1.75 thick, angle 20 for an outer diameter of 13.7".

Lamination Pro tells me to cut the board into 2 3/4" strips at 14 degrees.

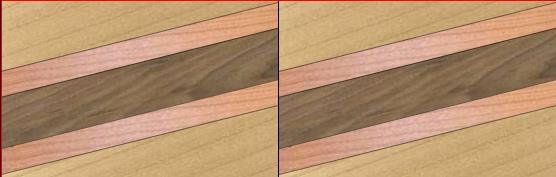

If you look at the diag-stripe lam file it shows the laminate needs to be cut at several angles to the the outside maple strips into a triangle shape. I need to crosscut the lamination at an angle then rip the pieces at an angle then somehow cut the bevel on the ends to make the circle.

How do you guys do this? Compound miter cuts short circuit my brain.

Thanks for your guidance,

Lee

I'm working on my 1st bowl and am perplexed on how to cut the feature ring lamination.

Segment Pro gives me a board width of 1.20, length 42.2, S.E.L. 5.0, 9 segments, 1.75 thick, angle 20 for an outer diameter of 13.7".

Lamination Pro tells me to cut the board into 2 3/4" strips at 14 degrees.

If you look at the diag-stripe lam file it shows the laminate needs to be cut at several angles to the the outside maple strips into a triangle shape. I need to crosscut the lamination at an angle then rip the pieces at an angle then somehow cut the bevel on the ends to make the circle.

How do you guys do this? Compound miter cuts short circuit my brain.

Thanks for your guidance,

Lee