Glenn McCarron

PRO Member

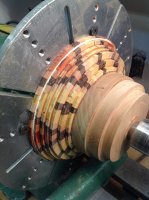

Stuart, for the sake of waste it would be better to start building rings from the biggest to the smallest as I could keep trimming my centre disc smaller thus only using one piece of material. Going smallest to biggest I have to sacrifice a new piece for each layer. They do come out easily so I will save them for the next project.Glenn, I don't know why I sent block instead of disc but I do like the idea.