What is the ring type wheel and when is it used?

-

Are you looking for a coupon code to buy my software? You can get one from lots of 3rd party sites but they won't work. My software never goes on sale and has never been discounted. The only coupon codes that are given is when I give a club presentation and I offer a discount to the attendees. Other than that, everyone pays the same price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Type Of Ring - Wheel

- Thread starter stuart johnson

- Start date

Jeff Miller

Moderator

Stuart,

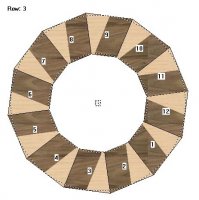

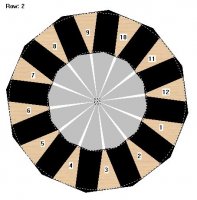

The wheel type ring is made of spacers that are a constant width between segments, where a flat ring is all segments (pie shaped). I have attached a test file that shows a flat ring (#2) and a wheel ring (#3). Using ring view will show the difference, the outside profile view looks pretty similar. Lloyd used the wheel type on a project, a captains clock, where he used the spacer to designate where the square spindles go through the wheel ring.

View attachment wheel type test.wtp

The wheel type ring is made of spacers that are a constant width between segments, where a flat ring is all segments (pie shaped). I have attached a test file that shows a flat ring (#2) and a wheel ring (#3). Using ring view will show the difference, the outside profile view looks pretty similar. Lloyd used the wheel type on a project, a captains clock, where he used the spacer to designate where the square spindles go through the wheel ring.

View attachment wheel type test.wtp

Stuart and Jeff,

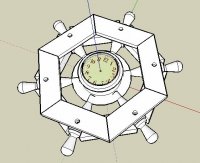

The Wheel Type ring is really fun and it opens a lot of design doors. The Ship's Wheel Clock is one of the most fun projects I've ever done and now I watch eBay for port hole clocks that have collectable qualities to them.

There are two other uses for this ring type that aren't really apparent. If you open Jeff's file and take a look at the Ring View, you'll see that the joints of the segments do not point to the center of the turning. If you were to place Jeff's ring at the top of a vessel where the wall profile is decreasing rapidly, the appearance will be curved lines instead of straight lines and this becomes a very easy way to achieve curved lines as the pie-shaped pieces are cut at 15% (in this case) identically to how you would have cut them for a Flat Type ring. You can contrast this with a similar, but very different look by adding another ring to his test file and switching it to Flat and add a vertical spacer of 1/2". In this case, one edge of the pie-shaped segment points to the center, but the joint between the vertical spacer (which is a segment with parallel sides) and the next segment point away from the center. Placed at the top of a vessel, this ring will give half straight lines and half curved lines where the Wheel Type will have all curved lines.

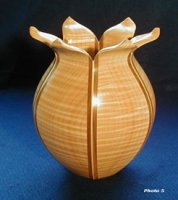

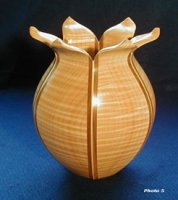

The other design capability with the Wheel Type is the 'Lost Wood' process, which I have only experimented with, but has been well-documented stave vessel project by Lowell Converse at this link and looks like this:

When you look at this turning, you'll see that it is not round but instead has six facets that are rounded. This is because the ring had six pie-shaped segments and six segments with parallel sides. The turning was made with all 12 segments assembled with double-sided tape and then the segments with parallel sides were removed. The test vessels I made using this process were very interesting in that it was puzzling to see a vessel that was turned on a lathe and yet wasn't round. The last test I made I attempted to simplify the turning of the inside by using a template on the parallel sides and bandsawing away the part that would be turned on the lathe. I even made a carriage that let me put the pie-shaped staves at their final angle and then band-sawed them using the same template. I need to get back to this style and explore it much further.

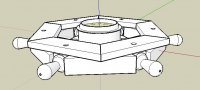

So if you're at all tired of making vessels that have the shape of 99.6 of all turned vessels, the Wheel Type will certainly open up a whole new world of woodturning to you. The Captain's Clock project is especially fun as it gives you a chance to do spindle turning, woodturning and woodworking all in the same project. The pie-shaped pieces of that project were cut on the table saw and then I used a pattern-maker process (undocumented, unfortunately) to cut both the inner and outer radii on the bandsaw. This made that process very fast and needed just minor sanding using a disk sander and a drum sander. A project like this can easily be done in a day - less, if you're really adept at spindle turning which I strive to be but have a long way to go. :-<

Lloyd

The Wheel Type ring is really fun and it opens a lot of design doors. The Ship's Wheel Clock is one of the most fun projects I've ever done and now I watch eBay for port hole clocks that have collectable qualities to them.

There are two other uses for this ring type that aren't really apparent. If you open Jeff's file and take a look at the Ring View, you'll see that the joints of the segments do not point to the center of the turning. If you were to place Jeff's ring at the top of a vessel where the wall profile is decreasing rapidly, the appearance will be curved lines instead of straight lines and this becomes a very easy way to achieve curved lines as the pie-shaped pieces are cut at 15% (in this case) identically to how you would have cut them for a Flat Type ring. You can contrast this with a similar, but very different look by adding another ring to his test file and switching it to Flat and add a vertical spacer of 1/2". In this case, one edge of the pie-shaped segment points to the center, but the joint between the vertical spacer (which is a segment with parallel sides) and the next segment point away from the center. Placed at the top of a vessel, this ring will give half straight lines and half curved lines where the Wheel Type will have all curved lines.

The other design capability with the Wheel Type is the 'Lost Wood' process, which I have only experimented with, but has been well-documented stave vessel project by Lowell Converse at this link and looks like this:

When you look at this turning, you'll see that it is not round but instead has six facets that are rounded. This is because the ring had six pie-shaped segments and six segments with parallel sides. The turning was made with all 12 segments assembled with double-sided tape and then the segments with parallel sides were removed. The test vessels I made using this process were very interesting in that it was puzzling to see a vessel that was turned on a lathe and yet wasn't round. The last test I made I attempted to simplify the turning of the inside by using a template on the parallel sides and bandsawing away the part that would be turned on the lathe. I even made a carriage that let me put the pie-shaped staves at their final angle and then band-sawed them using the same template. I need to get back to this style and explore it much further.

So if you're at all tired of making vessels that have the shape of 99.6 of all turned vessels, the Wheel Type will certainly open up a whole new world of woodturning to you. The Captain's Clock project is especially fun as it gives you a chance to do spindle turning, woodturning and woodworking all in the same project. The pie-shaped pieces of that project were cut on the table saw and then I used a pattern-maker process (undocumented, unfortunately) to cut both the inner and outer radii on the bandsaw. This made that process very fast and needed just minor sanding using a disk sander and a drum sander. A project like this can easily be done in a day - less, if you're really adept at spindle turning which I strive to be but have a long way to go. :-<

Lloyd

As long as we're on this topic, I'd like to point out something that is really confusing until you understand the difference between the Flat Type with a Vertical Spacer and the Wheel Type rings. If you add to Jeff's test file a Flat row with 1/2" Vertical Spacers and the switch to the Ring View, you'll notice that the pie-shaped segments from both rows are all identical and the spacer is 1/2" segment with parallel sides for both rows as well. So why is it that the same identical 24 pieces of wood make such dramatically different designs?

The answer can be explained (somewhat) by clicking individual segments from the Ring View of both rows. Start with the Flat View with Vertical Spacer and click on a segment and it will become outlined and show you that the pie-shaped segment is on one side and the parallel segment is glued to it. When you click on a segment in the Ring View, though, it appears that the segment with parallel sides has been cut in half and each half is glued to the outside of the pie-shaped segment.

In practice, though, this is not how it is done. In reality, you first cut the parallel-sided segments (the spokes) and orient them to the center (the hub of the wheel). The pie-shaped pieces, cut with the Segment Edge Length as shown in the calculations will slide toward the hub between the spokes and make contact with them and where that contact is made will form an outside diameter that was also shown in the calculations and that is where they are glued to the spokes.

Lloyd

The answer can be explained (somewhat) by clicking individual segments from the Ring View of both rows. Start with the Flat View with Vertical Spacer and click on a segment and it will become outlined and show you that the pie-shaped segment is on one side and the parallel segment is glued to it. When you click on a segment in the Ring View, though, it appears that the segment with parallel sides has been cut in half and each half is glued to the outside of the pie-shaped segment.

In practice, though, this is not how it is done. In reality, you first cut the parallel-sided segments (the spokes) and orient them to the center (the hub of the wheel). The pie-shaped pieces, cut with the Segment Edge Length as shown in the calculations will slide toward the hub between the spokes and make contact with them and where that contact is made will form an outside diameter that was also shown in the calculations and that is where they are glued to the spokes.

Lloyd

Randy Toney

PRO Member

Lloyd, I'm trying to use this Wheel type row, but I am not understanding your comment above: "... first cut the parallel-sided segments (the spokes) and orient them to the center...". Is there a technique for orienting the spokes to the center? I'm using Bill Smith's jig design for my open-segment glue-ups.

Thanks,

Thanks,

Lloyd, I'm trying to use this Wheel type row, but I am not understanding your comment above: "... first cut the parallel-sided segments (the spokes) and orient them to the center...". Is there a technique for orienting the spokes to the center? I'm using Bill Smith's jig design for my open-segment glue-ups.

Thanks,

Hi Randy.

Remember in WTP the ring view will print out the ring in the exact size. Print out the ring and use it as a guide to glue up your segments.

Works well for ring sizes that your printer can print out.

Randy,

When you use the wheel configuration, the spokes will ALWAYS point to the center of the vessel. The identical segments that go between the spokes will guarantee that this happens. This happens because the spokes have parallel sides. If you use the same segments and just substitute the spokes with wider spokes, the wheel will simply get larger.

As Mike has said, if you look at the ring view of a flat ring with vertical spacers, those spacers will never point to the center of the bowl because they are simply glued to one edge of a segment. In a wheel-type vessel, the parallel sided spokes are simply separated by the segments and so it is like the spoke was cut through the center and half was glued to each edge of the segment.

It is simply easier to glue vertical spacers to the edge of each segment which has the effect of making the Segment Edge Length bigger.

Wheels are a LOT of fun to do, but you have to come up with a way to make sure that the segments are positioned equidistant from the center of the vessel.

When you use the wheel configuration, the spokes will ALWAYS point to the center of the vessel. The identical segments that go between the spokes will guarantee that this happens. This happens because the spokes have parallel sides. If you use the same segments and just substitute the spokes with wider spokes, the wheel will simply get larger.

As Mike has said, if you look at the ring view of a flat ring with vertical spacers, those spacers will never point to the center of the bowl because they are simply glued to one edge of a segment. In a wheel-type vessel, the parallel sided spokes are simply separated by the segments and so it is like the spoke was cut through the center and half was glued to each edge of the segment.

It is simply easier to glue vertical spacers to the edge of each segment which has the effect of making the Segment Edge Length bigger.

Wheels are a LOT of fun to do, but you have to come up with a way to make sure that the segments are positioned equidistant from the center of the vessel.

Ken Sherwin

PRO Member

For my (and possibly others) education,, what is a wheel row?

Ken

Lloyd explained the wheel ring in the above posts. I have attached an example bowl. Ring 2 is a wheel ring with 1/2" spokes. Ring 3 is a flat ring with 1/2 spacers. Take a look at the rings in RING view. click on a segment and see how the spoke or spacer is attached.

hope this helps.

Lloyd explained the wheel ring in the above posts. I have attached an example bowl. Ring 2 is a wheel ring with 1/2" spokes. Ring 3 is a flat ring with 1/2 spacers. Take a look at the rings in RING view. click on a segment and see how the spoke or spacer is attached.

hope this helps.

Attachments

Here is one of my favorite projects and I used the Wheel type for it. It is a ship's wheel clock that uses a porthole clock as the centerpiece.This winter, I plan to make a tutorial project that shows some tips and tricks for building it.

I've attached a Woodturner PRO file that shows the wheel I made. I also modeled it in Sketchup mostly for practice and I've included some views from that file.

I've attached a Woodturner PRO file that shows the wheel I made. I also modeled it in Sketchup mostly for practice and I've included some views from that file.

Attachments

Ken Sherwin

PRO Member

I downloaded Woodturner Pro and opened your various plans. I believe I discovered that a wheel ring has some segments that are wedges and some that have parallel side (zero degree taper). Is that correct?

Ken: It is not technically correct. The difference between the flat ring with vertical spacers and a wheel ring with spokes is the alignment of the spacer or spokes. In my file I posted the spacer and the spoke are the same width. They both are rectangles 0.5" wide. The difference is in the alignment

Wheel ring - note that the sides of the segments do not point towards the center.

Flat ring - note the sides of the segments Point towards the center.

Wheel ring - note that the sides of the segments do not point towards the center.

Flat ring - note the sides of the segments Point towards the center.

Attachments

Ken Sherwin

PRO Member

Got it. Thanks.