Bluemax

PRO Member

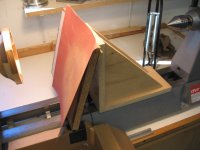

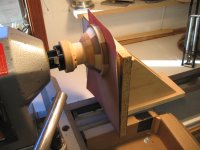

I'm a new member in the group and have a couple suggestions that might help some of the members. I notice most good turners use a lathe tool to face the rings flat on their turnings in prep for the next ring. In doing open segment turning in particular I'm a little leery of popping the segment off when I use that method. I made a angle plate that sits on my lathe bed that is perpendicular and square to the turning. I then mark the face with a pencil and rough or finish sand until pencil marks are gone (rough if it is a closed ring and finish if it is an open ring). This gives me a flat surface without worrying about popping a segment. This probably doesn't concern the good turners in the group but I'm not one of them. Also I use a free program called Greenshot for grabbing parts of a screen that I want to use. It will copy them to clipboard or other programs. I used it to print out the profiles in Seg Pro so I can look at them. I have that copied to Excel spread sheet if anyone is interested and LLoyd doesn't mind if I give the pictures out. I've also added some pictures of some of my work.