M

mcjayjay

Guest

A little background

Our shop has 900 members

1/3 are turners

1/3 of those do segmented bowls

I taught most all of them how to 'make' segmented bowls using Woodturner Pro & 3D Design Pro

We are 9500 sf and have 12 lathes, 5 tables saws, and most every woodworking tool one can imagine

All are Senior citizens

I started using chop saw

Then went to Incra

Then in-house made single fence sleds

Then wedgie style sled using pre-made Wedgies

All methods yield decent but not perfect results

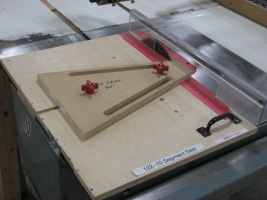

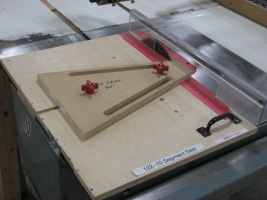

I took what I learned and built a new generation of sleds that are 100% dead nuts on 100% of the time.

I built 2 Segment sleds that are identical but tweaked for and paired with each table saw, we all know that the table saw top guide slots aren’t ever the same.

The angle guides are universal and are interchangeable between the sleds.

The table saw insert was made to be zero clearance with the sled bed to minimize segment cleanup.

The table saw insert is also angled using low friction material to allow the segments to fall away from the blade. (I've been able to safely accumulate more than 60 segments before clearing).

The angle guides were produced on a CNC and are the key to accuracy.

To swap angles just unscrew the knobs pop off the guide and pop on another.

The sleds are equipped with blade guards.

The guides have finger slots to help hold material while cutting and positioned to minimize blade hazards as well as having a blade guard.

The sled has a limit stop so it can’t be pulled or pushed too far in either direction.

The measurement length limit device is simply a block with 2 very strong rare earth magnets and rests against the saw rip fence.

Our shop has 900 members

1/3 are turners

1/3 of those do segmented bowls

I taught most all of them how to 'make' segmented bowls using Woodturner Pro & 3D Design Pro

We are 9500 sf and have 12 lathes, 5 tables saws, and most every woodworking tool one can imagine

All are Senior citizens

I started using chop saw

Then went to Incra

Then in-house made single fence sleds

Then wedgie style sled using pre-made Wedgies

All methods yield decent but not perfect results

I took what I learned and built a new generation of sleds that are 100% dead nuts on 100% of the time.

I built 2 Segment sleds that are identical but tweaked for and paired with each table saw, we all know that the table saw top guide slots aren’t ever the same.

The angle guides are universal and are interchangeable between the sleds.

The table saw insert was made to be zero clearance with the sled bed to minimize segment cleanup.

The table saw insert is also angled using low friction material to allow the segments to fall away from the blade. (I've been able to safely accumulate more than 60 segments before clearing).

The angle guides were produced on a CNC and are the key to accuracy.

To swap angles just unscrew the knobs pop off the guide and pop on another.

The sleds are equipped with blade guards.

The guides have finger slots to help hold material while cutting and positioned to minimize blade hazards as well as having a blade guard.

The sled has a limit stop so it can’t be pulled or pushed too far in either direction.

The measurement length limit device is simply a block with 2 very strong rare earth magnets and rests against the saw rip fence.