Ed Cuttle

PRO Member

Hi Lloyd

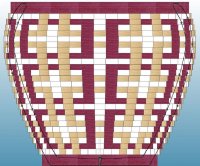

Just received the Segment Stomper and SegEasy plates. Will work on getting things setup this week. When you glue up each ring, what technique do you use to avoid glue squeezing into the open segment sides, do you sand each open segment after glue up to the next ring, and then, as I use Tung oil on almost all my segment projects, any trick to getting the finish from not building up in the open segment areas? Also, any special lathe speed to use as this is an open segment vs solid when turning?

Really looking forward to the first project, have it planed in Woodturner PRO. Thanks for any pointer and will get you a picture as I get started.

Thanks again

Ed Cuttle

Huntley, Il.

Just received the Segment Stomper and SegEasy plates. Will work on getting things setup this week. When you glue up each ring, what technique do you use to avoid glue squeezing into the open segment sides, do you sand each open segment after glue up to the next ring, and then, as I use Tung oil on almost all my segment projects, any trick to getting the finish from not building up in the open segment areas? Also, any special lathe speed to use as this is an open segment vs solid when turning?

Really looking forward to the first project, have it planed in Woodturner PRO. Thanks for any pointer and will get you a picture as I get started.

Thanks again

Ed Cuttle

Huntley, Il.