David Muehlbauer

PRO Member

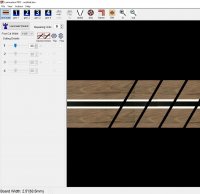

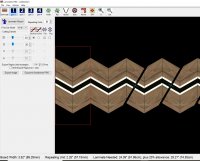

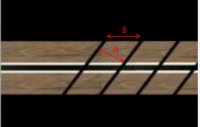

I have designed a bowl in Segment Pro with a Feature Ring. I designed the Feature Ring in Lamination Pro, but 'First Cut' doesn't work the way I understand the term. The Segment Edge Length I need is 2 3/16" (aka 2.385"). So if I used one-half of that for the 'First Cut' in Lamination Pro, and a 30° angle, the segment width says 2.5", but that isn't what happens. If I measure 1 1/4" along the edge of the laminated strip and cut my 30° angle with my miter saw my chevron is not going to be 2.5" wide because I am angling the two slices before I glue them together. By doing my own calculations I determined that I have to cut it 1 5/16" to get a chevron 2 1/4" wide. The larger the angle, the longer the slice needs to be.

What am I missing here? I am not a math wizard but it seems that in Lamination Pro, changing the angle should either change the First Cut or change the Repeating Unit.

What am I missing here? I am not a math wizard but it seems that in Lamination Pro, changing the angle should either change the First Cut or change the Repeating Unit.