K

kweinert

Guest

And I'm not sure if it's me or the software.

Probably me.

So I have my first design and it's not coming out like the instructions lead me to believe. So before I go farther I thought I'd check in here.

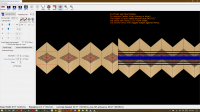

So this is what the design should look like.

I measured the original strips correctly:

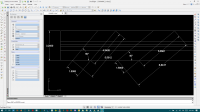

And I believe I cut on the specified 40 degree angle:

But the resulting width is *much* taller than the pattern says it should be:

(Pattern says 5.45")

The individual slices are the correct width as well.

And I ended up with only 10 repetitions instead of 12.

This leads me to believe that the measurements for cutting out the center won't work as given. I also suspect that even if I make the adjustment to cut out the center 1/2" that the southwest pattern don't look as I want it to.

Any thoughts from those of you with more experience? Where did I go wrong?

Thanks.

Probably me.

So I have my first design and it's not coming out like the instructions lead me to believe. So before I go farther I thought I'd check in here.

So this is what the design should look like.

I measured the original strips correctly:

And I believe I cut on the specified 40 degree angle:

But the resulting width is *much* taller than the pattern says it should be:

(Pattern says 5.45")

The individual slices are the correct width as well.

And I ended up with only 10 repetitions instead of 12.

This leads me to believe that the measurements for cutting out the center won't work as given. I also suspect that even if I make the adjustment to cut out the center 1/2" that the southwest pattern don't look as I want it to.

Any thoughts from those of you with more experience? Where did I go wrong?

Thanks.