That is good to know. It is the same pattern I used on the original Acoma, I just changed the profile

-

Are you looking for a coupon code to buy my software? You can get one from lots of 3rd party sites but they won't work. My software never goes on sale and has never been discounted. The only coupon codes that are given is when I give a club presentation and I offer a discount to the attendees. Other than that, everyone pays the same price.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Open Segment Project - Acoma-2

- Thread starter Bob Beaupre

- Start date

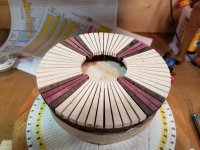

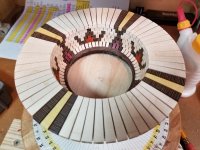

Using Tom Lohman's new process of doing closed segment rings on a open segment glue up jig.

Using the jig to glue ever third segment

View attachment 3579

View attachment 3580

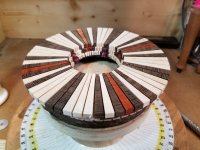

Let segment dry

Then insert segment pairs in between

View attachment 3581

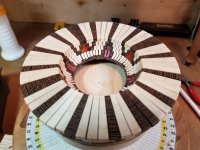

View attachment 3582

Now completely glued (not perfect but good enough with extra on the ID and OD)

View attachment 3583

Works good on those thin rings

No clamps no rubber bands

Can stop half way in a ring glue up

Bob:

In using the jig for closed segment rings did you cut all the segments to the specified segment edge length or did you have to cut some longer/shorter to fit between the every third glued segment?

I am looking at possibly building a jig like the one on the carbatec web site. I think it may help in my building 36 - 60 segment rings.

Title: Open Segment Jig

Another possibility is just to bite the bullet and order from Tom L.

I cut the segments just like I would for using a normal clamping method.

Mike I had a jig like that and was only satisfied with it up to 24 segments.

Have you checked Tom's site lately he has made some changes to his index rings for the better

Mike I had a jig like that and was only satisfied with it up to 24 segments.

Have you checked Tom's site lately he has made some changes to his index rings for the better

I need to check out Tom's site. It has been awhile since I visited.

Thanks for the tip on the jig being good up to 24. Right now I have been working with 36 segments. Seems it doesn't matter if I use my incra sled or a seg easy sled about half my rings do not come out perfect. I do build half rings. Some need touch up , some don't. I have not found a good way to glue up 36 segments all at once. The glue tends to set before I get everything glued.

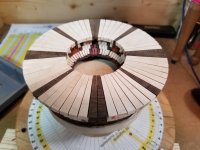

Your bowl looks great so far. Very nice bottom design.

Thanks for the tip on the jig being good up to 24. Right now I have been working with 36 segments. Seems it doesn't matter if I use my incra sled or a seg easy sled about half my rings do not come out perfect. I do build half rings. Some need touch up , some don't. I have not found a good way to glue up 36 segments all at once. The glue tends to set before I get everything glued.

Your bowl looks great so far. Very nice bottom design.

The other thing that I have made since I did this pattern for Acoma is to change the open segment gaps. Acoma had a one deg gap when Acoma-2 the gap is reduced to 12%.

For comparison:

The row I just put on is 5" OD

A row with 1 deg gap the gap = 0.0437

A row with a 12% gap the gap = 0.315

At it's biggest diameter of 12" OD

A row with 1 deg gap the gap = 0.1050

A row with a 12% gap the gap = 0.0756

Just a tighter open gap

For comparison:

The row I just put on is 5" OD

A row with 1 deg gap the gap = 0.0437

A row with a 12% gap the gap = 0.315

At it's biggest diameter of 12" OD

A row with 1 deg gap the gap = 0.1050

A row with a 12% gap the gap = 0.0756

Just a tighter open gap

Glenn McCarron

PRO Member

Bob, when does the medallion get added or why don't you see it in your picture?

I don't know! This is my first one. The ID of the opening at the bottom is not tuned to its final dimension yet. I want to get at least two segments rows on so I can turn it and put the tapper that will go down to the medallion. It most likely will not be up in until the very end. No way of putting it in now, until I break it loss from the waste block. I guess I'll worry about it then. It is turned and will fit into the counter bore at the bottom with a little extra room for expansion. I'll also finish it before putting it in. The retaining ring for the medallion ring now it a solid dish attached to a face plate, that I can use for centering if needed. When it come to the end I will have to cut the ID of the ring and cut it to a finial thickness.

Glenn McCarron

PRO Member

Looking good. When is the first turning planned?

Looking good. When is the first turning planned?

Pretty soon, I'm waiting for the ID to open up a little more so the pieces that go on next have more support on the ID. The ID down at the bottom will have to be cut to about 3" ID and then the base tapper cut to blend down to the medallion that will be inserted from underneath.

I have a new favorite tool for turning the ID on my open segment work. At the symposium Mike Hunter from Hunter Tools had a booth set up and had a show special on some of his tools.

I bought four of them!!

I got :

#1 Hunter Osprey

#2 Hunter Osprey

#3 Shallow Swan Neck

#3 Full Swan Neck

For the turning I did above I used the small #1 Hunter Osprey and it shaved those lettle segments perfectly.

Nice tool I would recommend it.

I bought four of them!!

I got :

#1 Hunter Osprey

#2 Hunter Osprey

#3 Shallow Swan Neck

#3 Full Swan Neck

For the turning I did above I used the small #1 Hunter Osprey and it shaved those lettle segments perfectly.

Nice tool I would recommend it.

Glenn McCarron

PRO Member

Did you use the tool right from the start of the turning or did you sand the corners off first?

right from the start, a little sanding after though